Bio Insights

Explore the latest trends, technologies, and success stories in Bioprocessing.

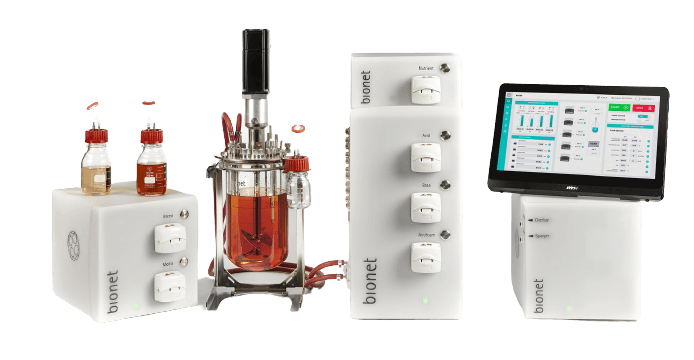

Enhancing Monoclonal Antibody Production:

How BIONET’s F0-BABY Bioreactor is Advancing Trastuzumab Manufacturing

In the rapidly evolving world of biopharmaceutical manufacturing, the pressure to produce high-quality monoclonal antibodies efficiently and consistently has never been greater.

This article takes a closer look at a promising development in the field — the successful use of BIONET’s F0-BABY bioreactor system to manufacture Trastuzumab, a life-saving therapy for HER2-positive breast cancer, using Chinese Hamster Ovary (CHO) cells.

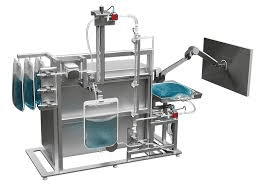

Maximize Bioprocess Efficiency with Tezalon’s Single-Use TFF System

How Biogentek Helps You Reduce Loss, Improve Yield & Simplify Scale-Up

In the high-stakes world of bioprocessing, every drop of your therapeutic product counts. That’s why Biogentek, in collaboration with our trusted partner Tezalon, is proud to spotlight an intelligent innovation that’s changing the game in Tangential Flow Filtration (TFF) — the single-use recirculation testing system.

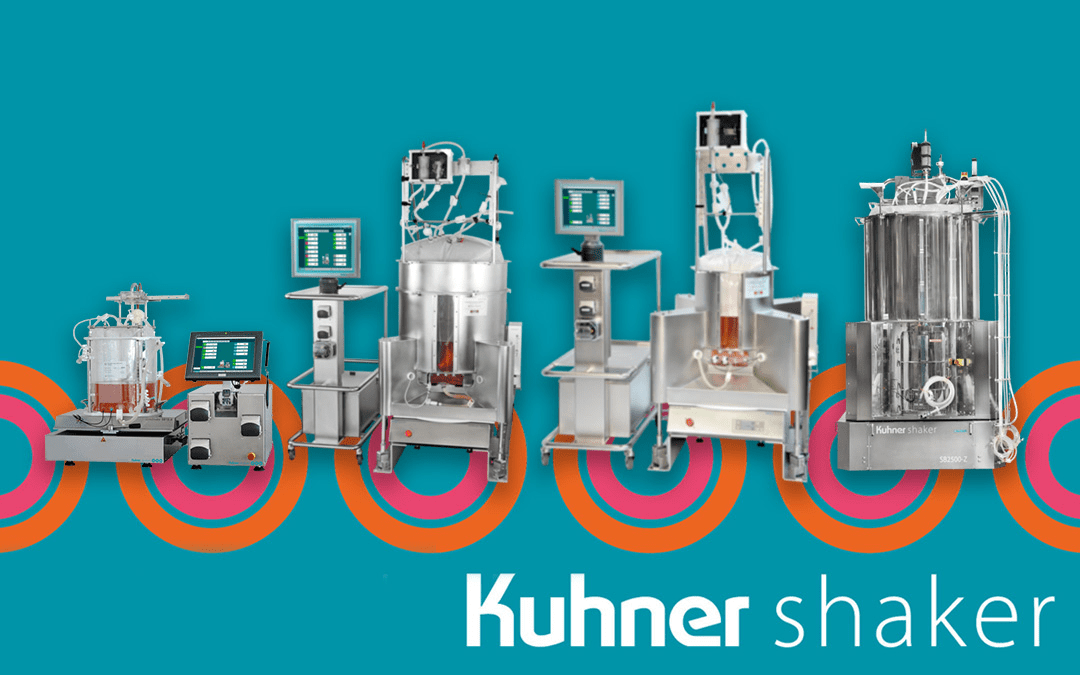

Bioreactors for Fast-Paced CRO/CDMO Labs – Kuhner OSB

Are Your Bioreactors Keeping Up with Your CDMO/CRO's Pace?

Discover how Kuhner’s Orbital Shaken Bioreactors are transforming bioprocessing efficiency, scalability, and flexibility for modern CDMO and CRO labs.

Revolutionizing Bioprocessing with BIONET’s F1 Bioreactor: A Leap into Semi-Continuous Cultivation

The Bioprocessing Bottleneck: Challenges with Traditional Methods

In traditional batch and fed-batch bioprocessing, every production cycle demands extensive cleaning, sterilization, and inoculum preparation. These steps are time-consuming and resource-intensive, making scalability and responsiveness difficult—especially in commercial-scale production of recombinant proteins.

To solve this, BIONET has introduced a smarter, more efficient alternative: semi-continuous cultivation powered by their advanced F1-3L bioreactor and Continuous Process Module (CPM).

Cell-tainer® 2D Rocking: A Game Changer in Single-Use

Bioreactors

The lack of a single-use system that functions equally well for microbial and mammalian

processes, limited oxygen transfer in wave motion bioreactors, and difficulty in scaling up

without sacrificing culture performance are all typical problems faced during bioprocessing.

These issues are directly addressed by Bionet's Cell-tainer®. Its revolutionary patented 2D